Grinding films

The standards for optical connectors contain strict specifications for the geometric and transmission technical parameters of the connectors. Therefore, an important part of the assembly of optical connectors is the design of the correct front surface, which is achieved through various grinding steps. Achieving standard-compliant radii of curvature, sphericity, surface smoothness, scratch resistance and, finally, the effect of these parameters on insertion and reflection attenuation requires considerable technological expertise, an important element of which is the use of abrasives of the right quality.

NTT-AT's abrasive films stand out from the competition due to their long life and high quality and, due to their good value for money, are very popular as essential auxiliary materials for quality mass production.

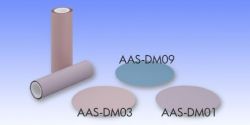

The range is available in three grades of industrial diamond abrasive film: AAS-DM09: 9um, AAS-DM03: 3um and AAS-DM01: 1 um. These are mainly used to adjust the geometric parameters. They are available in a 127mm round or 113mmx140mm rectangular format. The different grain sizes are available in different colours, making them easily distinguishable.

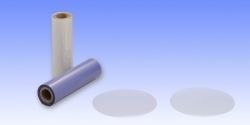

Another part of the range is the so-called finishing film (ADS) based on silicon dioxide (SiO2), which creates a fine surface structure, ensuring excellent reflectance attenuation values (UPC). The transparent film is available in a 127mm circle and a 113mmx140mm rectangle.