Air separation systems

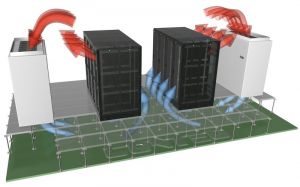

Hot / Cold Aisle

The open Hot/Cold Aisle arrangement is considered to be the "standard" for data center designs. Racks are aligned front to front and cold air is delivered using the raised floor as a cold air handling space (plenum). The ANSI/TIA/ EIA-942-A (data center) standard recommends a cold aisle width of 1.2 metres (which is equivalent to two floor tiles) to allow a perforated tile to be placed in front of each cabinet which allows for cold air to be delivered to the cabinet front.

PLENUM FEED WITH ROOM RETURN

This solution optimizes the use of cooled air by directing the cold air directly from the raised floor to the equipment within the rack. The rack sits on a special positioning welded frame which replaces a standard 600 x 600 floor tile. A deflector located in the bottom of the rack directs the cold air to the front of the rack to be drawn through the equipment mounted inside. Cold air is kept within the rack by a solid front door and hot exhaust air is rejected into the room through a vented rear door ensuring that cold supply and hot exhaust airstreams remain separated leading to more efficient use of the cooled air and elimination of hot spots.

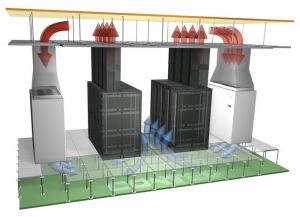

ROOM FEED WITH PLENUM RETURN

A potential drawback with Contained Cold Aisle and Direct Feed / Room Return technologies is that the hot exhaust is introduced into the facility. Generally this should not pose a problem as long as the layout of the data center takes this into account. However, in certain very high density applications it may be desirable to completely separate the hot exhaust.CONTEG's Hot Plenum Return Kit addresses this requirement by using a vertical "chimney" at the top rear of the rack directly connected to a hot plenum at ceiling height. The hot air is removed from the plenum by CRAC units, cooled again and delivered back to the room. The rack is equipped by front vented door, so the cold air can easily enter the rack space, where it is sucked in by the installed equipment.

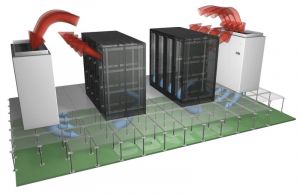

CONTAINED COLD AISLE

One of the potential drawbacks with the open Hot/Cold aisle arrangement is the risk of hot air recirculation and hot-spots. With CONTEG Contained Cold Aisle (CCA) solution, the containment system is used to physically separate cooled air from hot exhaust by forming a cold plenum space and preventing mixing of hot and cold air, thereby eliminating hot-spots. The cold air is supplied into the contained aisle through perforated tiles from the raised floor or produced locally by CoolTeg units which are installed directly in the row of cabinets as an integral part of the aisle. Standard width of CCA is 1.2m (two perforated tiles) or 1.8m (three perforated tiles) and containment can be deployed with standard swing doors or dual leaf sliding doors. To use Contained Cold Aisle is highly recommended to maximize cooling efficiency and minimize energy consumption of the entire Datacenter.

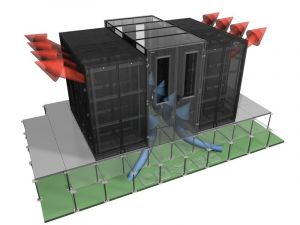

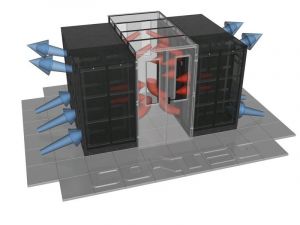

CONTAINED HOT AISLE

In cases where there is no raised floor for cold air delivery or the room dimensions do not support contained cold aisle deployment, the best way is to use the CONTEG Contained Hot Aisle (CHA) together with CoolTeg units. With CONTEG Contained Hot Aisle (CHA) solution, the containment system is used to physically separate cooled air from hot exhaust by forming a hot plenum space and preventing mixing of hot and cold air, thereby eliminating hot-spots. Racks are aligned back to back and hot air is contained at the rear of row of cabinets where it is cooled by the CoolTeg units which are positioned directly in the row of cabinets as an integral part of the aisle. The cold air is blown out of CoolTeg units and it´s delivered directly at the front of active IT equipment. Standard width of CHA is 1m, can be also 1.2m or 0.8m wide and containment can be deployed with standard swing doors or dual leaf sliding doors. To use Contained Hot Aisle is highly recommended to maximize cooling efficiency and minimize energy consumption of the entire Datacenter.

CONTAINED COLD/HOT AISLE

The contained cold/hot aisle solution is most effective way how maximize cooling capacity and minimalize operational costs. It isused for separation of hot and cold zones and can be used to close (separate) one of them.

Standard Contained Aisle System

One of the potential drawbacks with the open Hot/Cold aisle arrangement is the risk of hot air recirculation and hot-spots. With CONTEG Contained Cold Aisle (CCA) or Contained Hot Aisle (CHA) solution, the containment system is used to physically separate cooled air from hot exhaust by forming a cold plenum space and preventing mixing of hot and cold air, thereby eliminating hot-spots.

Modular Contained Aisle System

Cabinets from different manufacturers of varying heights, widths and depths are added to existing installations without any consideration that one day might be required to roof the area that is being supplied by cooled air. Modular Contained Aisle for traditional hot/cold aisle layouts is the right containment solution when higher cooling efficiency is needed, but the rack infrastructure cannot be changed and fitting the standard contained aisle is limited for any reason.

Modular Closed Loop Solutions

The Closed Loop architecture offers the ability to achieve up to 36kW per rack of cooling capacity in one specific assembly. This type of architecture can be especially useful when planning to install a few very high density racks into a facility as the racks do not release any heat out into the data center environment.

Side-To-Side Airflow Solution – STS

In the distribution area of data centers some vendors’ core networking equipment is not configured for typical entry from the front and exit from the rear cooling air flow, but instead utilizes a system where the cooling air enters from one side and exits from the other. In a standard cabinet this side to side cooling system can be problematic for equipment in the adjacent and nearby cabinets.